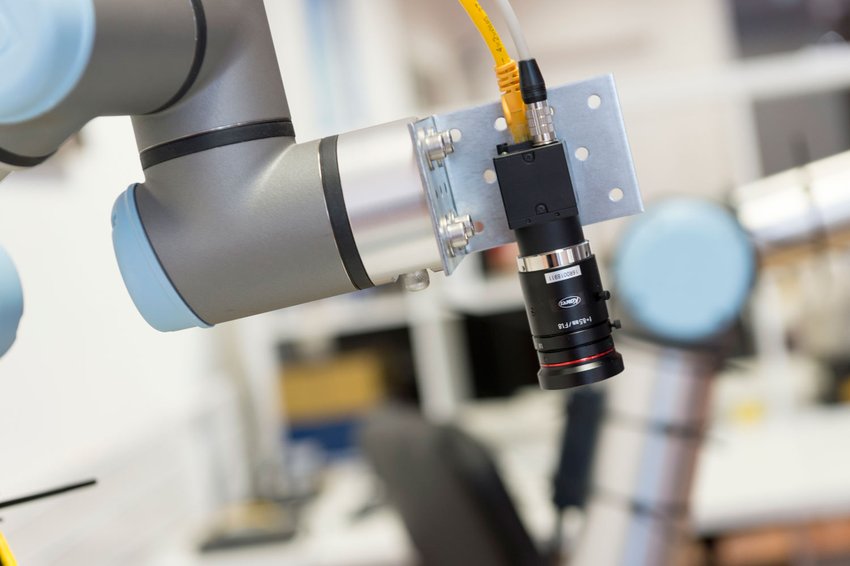

Artec 3D is a global leader in handheld 3D scanners that has been at the forefront of innovative 3D technology since 2007. The company develops and manufactures the high quality, yet easy to use portable 3D scanners, smart, user-friendly 3D software and an SDK that provides the best integration possibilities, whatever the application. With a worldwide presence and a large number of global clients, Artec 3D supplies state of the art 3D technology to these respective areas.

Always seeking to innovate, Artec 3D is constantly striving to offer its clients the most advanced in 3D technology, releasing a next generation scanner every one or two years and new scanning software every 12 months.

While handheld 3D scanners constitute its core business, Artec also develops biometric 3D recognition technology and one-click 3D body scanning solutions.

Their line of portable, handheld 3D scanners is specifically developed to ensure that they can be used by both new and experienced users alike for multiple applications, providing the most seamless workflow yet. Driven by passion and determination, Artec 3D constantly improves its 3D solutions to ensure the most cost and time-effective operations for their customers.

Interview with Artem Yukhin, president and CEO

What projects are you currently working on ?

Artec 3D constantly strives to develop and provide the simplest 3D scanning technology for achieving professional results. We create high precision, user-friendly scanners. Our line of portable, handheld 3D scanners is specifically developed to ensure maximum ease of use and user-friendliness for multiple applications, providing the most seamless workflow yet. In Autumn, we will lauch Artec Leo, a smart professional 3D scanner, which is able to provide the most intuitive workflow, making 3D scanning as easy as taking a video. As you scan your object, you see the 3D replica being modelized in real time on Leo's touch panel screen. This allows you to check if you have captured all areas, and fill in any parts you may have missed.

What successes are you particularly proud of ?

I'm proud of the facts that a lot of people and companies are using our scanners in many different applications ranging from quality control to cultural heritage and from rapid prototyping to medical applications. Our products are also commonly used to create assets for video games as well as visual effects for movies and TV shows, for instance in the last Terminator movie with Arnold Schwarzenegger fighting an older "scanned" version of himself. The scanner was also used to create the very first presidential 3D portrait of Barack Obama. Scientists and surgeons have been using 3D scanning technology to study and to build prosthesis, paleontologist to share their discoveries with colleagues all around the world, not to forget many other applications for industrial designers and graphic artists... Our scanners can be used to capture anything from the size of a shoe to that of a car with a point accuracy of up to 0,1mm.

What are the biggest challenges your sector is facing ?

We are still a start-up with a small team, making hardware production our biggest challenge. In our case, the production time for a scanner is very long, and if you make any mistake you pretty much have to start back from scratch. It adds up to one more year of production time and it is consequently very expensive. That's not a major problem for big company, but for us it is critical. We cannot allow ourselves to make mistakes!

If you could change one thing about your sector, what would it be? How could the Chamber of Commerce support you ?

The problematic area in our business is that we currently have to import all of the raw materials and spare parts used for our production to Luxembourg for assembly, and then export the finished goods, which is a very expensive process. We would like to set the whole manufacturing, including base material and spare parts, here in Luxembourg to curb on costs. Any help from the Chamber of Commerce in making this plan a reality is welcome.

Photos: Emmanuel Claude / Focalize